Cardboard Corner Board Making Machine

Cardboard Corner Board Making Machine Specification

- Type

- Edge Protector Machine

- Material

- Stainless Steel

- Feature

- Rust Proof, Highly Efficient, Less Power Consumable, Durable

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 24.5 Watt (w)

- Voltage

- 220-440 Volt (v)

- Weight (kg)

- 5000 Kilograms (kg)

- Dimension (L*W*H)

- 25000*1300*1700 Millimeter (mm)

- Color

- Blue & White

- Warranty

- 1 Year

Cardboard Corner Board Making Machine Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- shanghai

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 50 Sets Per Month

- Delivery Time

- 3 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- A Full 40FT container loading for cardboard corner board machine

- Main Export Market(s)

- Western Europe, Middle East, Central America, South America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

- Certifications

- CE

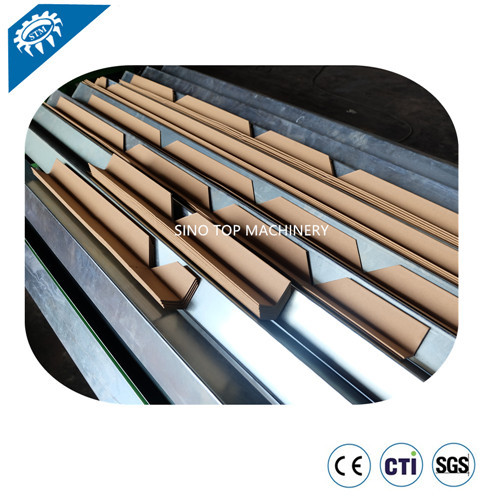

About Cardboard Corner Board Making Machine

Features :

- PLC control panel

- long time service life

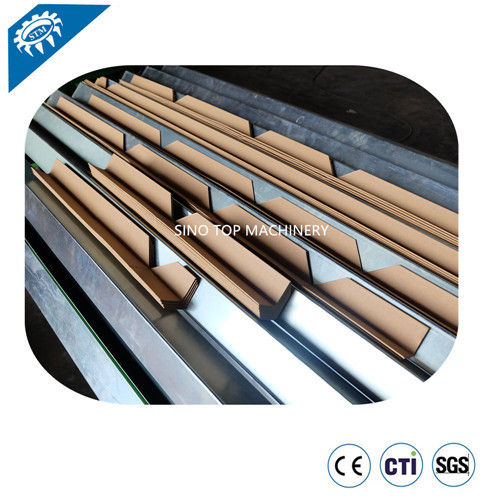

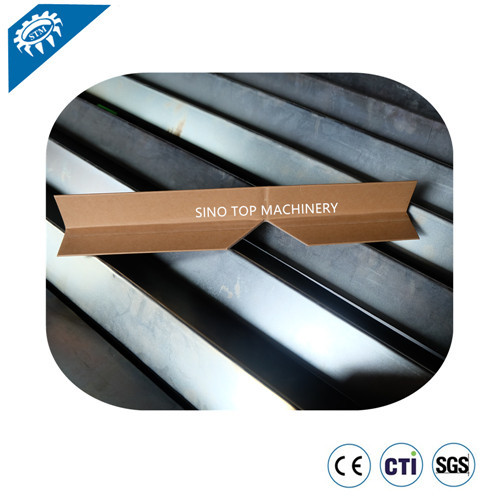

- make drier and harder edge protector

- Heating function

- one machine can make both flat laminating cardboard and edge protector

- crane and pneumatic way to load paper reels, safely and easy

- smart but useful

Advantages:

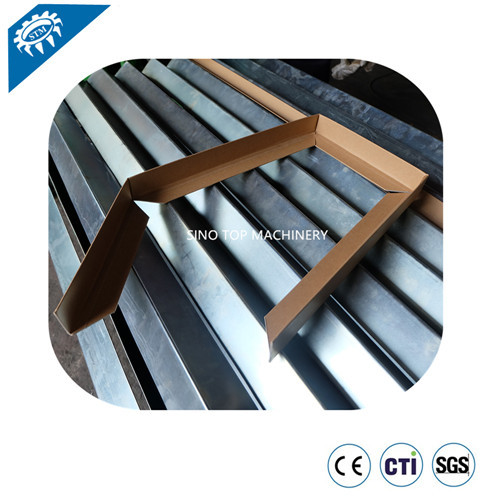

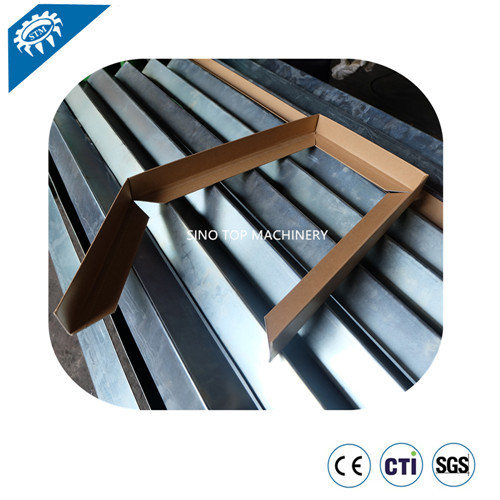

- Large size range for wing width :15mm-120mm

- larger range of thickness: 1.5-10mm

- both single and double sides gluing

- no limited of length

- online shortest cutting length at 50mm

- punching corners online

- automatic stacking

- Single color printing online

Applications:

- one machine can make both flat board and V shape edge protector

- one machine can make both flat board and U shape edge protector

- you can choose one machine one shape or one machine with different shapes

- 50mm length cutting online

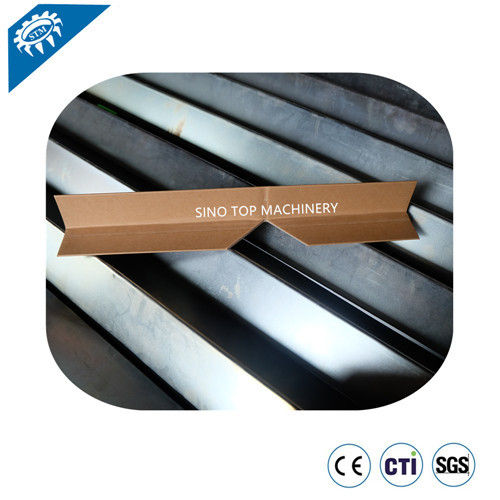

- to make paper edge protector for packing

Technical Specifications :

|

Model |

ZHJ-120AS |

|

Width |

15-120mm |

|

Wall Thickness |

1.5-10mm |

|

Speed |

0-45m/min, speed depends on edge board sizes and paper quality |

|

Cutting Length |

50mm-endless |

|

Cutting Accuracy |

1 mm |

|

Power |

120A-24.5KW/Automatic Collection: 1.9KW |

|

Max Layer of Paper |

13 layers + 1 surface |

|

Paper demanding |

Surface Kraft paper 160g, inner paper 300g |

|

Cutting way |

Servo cutting, fly shear |

|

Gluing way |

Both single and double faced |

|

Overall size |

L25000*D1300*H1700mm (including automatic collection) |

|

Total Weight |

5 Ton |

|

Operation |

2 persons |

Automated Efficiency for Edge Protector Production

This Cardboard Corner Board Making Machine delivers consistent, high-volume output with fully automatic operation and PLC control. The automated system optimizes the manufacturing process, ensuring uniformity in each cardboard corner board, while significantly reducing labor costs and manual intervention. Its less power-consumable design means operational savings over time, making it an ideal solution for large-scale manufacturing.

Robust Construction and User-Friendly Design

Constructed from rust-proof stainless steel and high-grade paper materials, this machine boasts a sturdy structure that ensures long-lasting performance. Despite its solid 7000-kilogram weight, its intuitive interface-with computerized and manual options-allows seamless operation, maintenance, and troubleshooting, enhancing user experience and machine longevity.

FAQ's of Cardboard Corner Board Making Machine:

Q: How does the Cardboard Corner Board Making Machine operate?

A: This machine uses electric power and PLC automation to process paper and stainless steel materials into finished cardboard corner boards. Simply feed the raw material, set parameters through the control panel, and the machine will automatically produce up to 5000 kg of corner boards per day.Q: What are the main benefits of using this machine for production?

A: Key benefits include high production capacity, automatic operation with PLC control, rust-proof durability, low power consumption, and the ability to produce uniform edge protectors with minimal manual input, resulting in cost savings and increased efficiency.Q: When is maintenance required for this machine?

A: Routine maintenance-such as checking the control system, cleaning mechanical parts, and ensuring proper lubrication-should be performed according to the manufacturer's guidelines, usually after stipulated operating hours or at least once per quarter to prolong machine life.Q: Where can the Cardboard Corner Board Making Machine be installed?

A: Given its sizable dimensions (up to 25 meters long and 3.5 meters wide), the machine is suitable for spacious industrial settings, such as factories or dedicated manufacturing workshops, with compatible electric supply and ventilation.Q: What is the process flow for making cardboard corner boards using this machine?

A: The process begins with loading raw paper and stainless steel material into the feeding section. The automated system then forms, presses, and cuts the boards to the specified size, with quality checks integrated during production for consistent output.Q: Can this machine be used for different sizes and types of edge protectors?

A: Yes, its PLC control system allows for parameter adjustments, letting users customize board dimensions and thicknesses to meet varying packaging needs, suitable for diverse applications in shipping and warehousing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Edgeboard Notching Machine 120AS Category

Paper Edge Protector Machine

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Voltage : 220440 Volt (v)

Material : paper

U Profile Edge Protector Machine

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Voltage : 220440 Volt (v)

Material : Stainless Steel

Paper Flat Cardboard and Angle Board Machine

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Voltage : 220440 Volt (v)

Material : Stainless Steel

V Notching Corner Protector Machinery

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Voltage : 220440 Volt (v)

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry