Paper Edge Protector Machine

Price 28000 USD ($)/ Set

Paper Edge Protector Machine Specification

- Type

- Other

- Material

- Stainless Steel

- Feature

- Rust Proof, Durable, Less Power Consumable, Highly Efficient

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 24.5 Watt (w)

- Voltage

- 220-440 Volt (v)

- Weight (kg)

- 5000 Kilograms (kg)

- Dimension (L*W*H)

- 25000*1300*1700 Millimeter (mm)

- Color

- Gray& Blue

- Warranty

- 1 Year

Paper Edge Protector Machine Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- shanghai

- Supply Ability

- 50 Sets Per Month

- Delivery Time

- 3 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- a full 40HQ container for edge protector machines

- Main Export Market(s)

- Western Europe, Central America, North America, Eastern Europe, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- CE

About Paper Edge Protector Machine

Features:

- Robust construction

- Optimum performance

- Easy installation

- PLC control panel

- long time service life

- make drier and harder edge protector

- Heating function

- one machine can make both flat laminating cardboard and edge protector

- crane and pneumatic way to load paper reels, safely and easy

- smart but useful

Advantages:

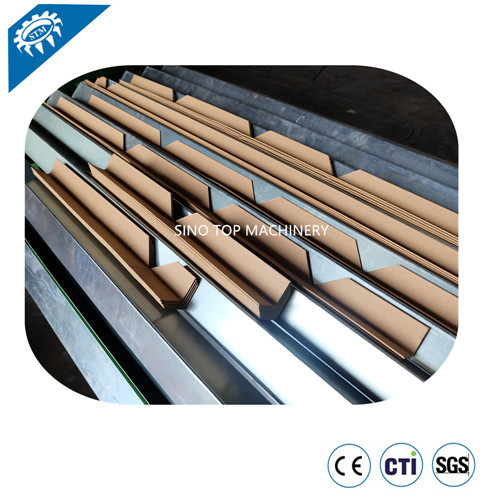

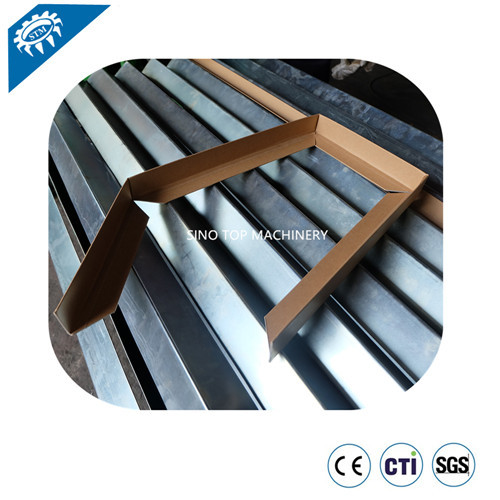

- Large size range for wing width :15mm-120mm

- larger range of thickness: 1.5-10mm

- both single and double sides gluing

- no limited of length

- online shortest cutting length at 50mm

- punching corners online

- automatic stacking

- Single color printing online

Applications:

- one machine can make both flat board and V shape edge protector

- one machine can make both flat board and U shape edge protector

- you can choose one machine one shape or one machine with different shapes

- 50mm length cutting online

- to make paper edge protector for packing

Technical Specifications :

|

Model |

ZHJ-120A |

|

Width |

15-120mm |

|

Wall Thickness |

1.5-10mm |

|

Speed |

0-45m/min, speed depends on edge board sizes and paper quality |

|

Cutting Length |

50mm-endless |

|

Cutting Accuracy |

1 mm |

|

Power |

120A-24.5KW/Automatic Collection: 1.9KW |

|

Max Layer of Paper |

13 layers + 1 surface |

|

Paper demanding |

Surface Kraft paper 160g, inner paper 300g |

|

Cutting way |

Servo cutting, fly shear |

|

Gluing way |

Both single and double faced |

|

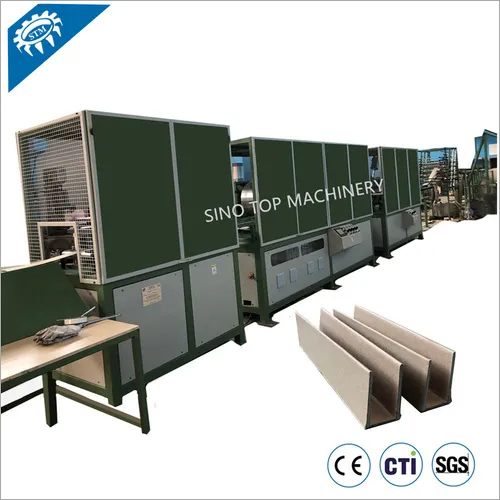

Overall size |

L25000*D1300*H1700mm (including automatic collection) |

|

Total Weight |

5 Ton |

|

Operation |

2 persons |

Efficient Edge Protection Solution

This machine automates the production of paper edge protectors using a reliable PLC control system. Its stainless steel construction and rust-proof design make it highly durable for continuous industrial use, while the electric drive minimizes energy consumption. Suited for large-scale packaging requirements, it delivers consistent results, streamlining protective packaging processes.

Flexible Design for Varied Needs

With dimension options of 25000*1300*1700 mm and 25*1.5*2.2 meters, this machine adapts to assorted factory setups. The choice of gray & blue or white & blue colors ensures aesthetic compatibility, and its computerized and automatic grades guarantee ease of operation regardless of operator expertise.

FAQ's of Paper Edge Protector Machine:

Q: How does the Paper Edge Protector Machine improve packaging efficiency?

A: The machine automates edge protector production using advanced electric drive and PLC control, ensuring consistent output and reduced manual intervention, which streamlines packaging and enhances efficiency.Q: What materials and features contribute to the machine's durability?

A: Constructed from stainless steel and paper, the Paper Edge Protector Machine is rust-proof and designed to withstand rigorous usage, ensuring long-term durability and minimal maintenance.Q: When is this machine ideally deployed in manufacturing processes?

A: It's best utilized in packaging lines that require heavy-duty edge protectors, especially for goods that need reinforced protection during transportation and storage.Q: Where can I purchase or source the Paper Edge Protector Machine?

A: The machine is distributed, exported, manufactured, supplied, and traded by various companies in China, making it readily available across international markets.Q: What is the process for operating the machine, and does it require technical expertise?

A: The operation is streamlined with PLC controls and automatic or computerized options. Basic training allows operators to manage production efficiently without deep technical knowledge.Q: What are the primary benefits of using this edge protector machine?

A: Key benefits include rust-proof durability, less power consumption, high production capacity (up to 6,000 kg), and a one-year warranty-all contributing to reduced costs and reliable performance.Q: How does the tubular heater and electric drive contribute to the machine's operation?

A: The tubular heater provides efficient heating for shaping paper protectors, while the electric drive ensures consistent movement and high production efficiency at reduced power usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Edgeboard Notching Machine 120AS Category

Automatic U shape and flat board edge protector machine

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Voltage : 220440 Volt (v)

Warranty : 1 Year

Paper Flat Cardboard and Angle Board Machine

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Voltage : 220440 Volt (v)

Warranty : 1 Year

V Notching Corner Protector Machinery

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Voltage : 220440 Volt (v)

Warranty : 1 Year

Cardboard Corner Board Making Machine

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Voltage : 220440 Volt (v)

Warranty : 1 year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry