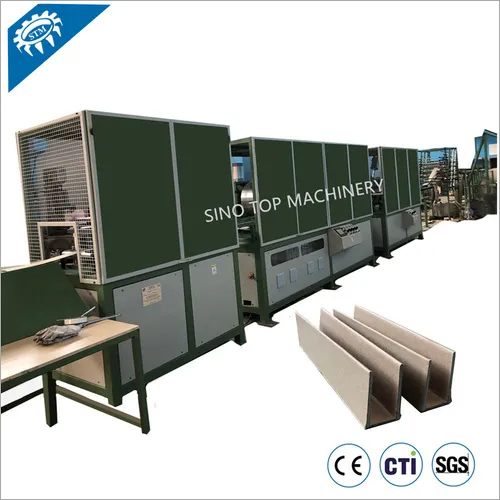

V Notching Corner Protector Machinery

Price 28000 USD ($)/ Set

V Notching Corner Protector Machinery Specification

- Type

- Edge Protector Machine

- Material

- Stainless Steel

- Feature

- Rust Proof, Durable, Highly Efficient

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 25 Watt (w)

- Voltage

- 220-440 Volt (v)

- Weight (kg)

- 5000 Kilograms (kg)

- Dimension (L*W*H)

- 24000*1200*1500 Millimeter (mm)

- Warranty

- 1 Year

V Notching Corner Protector Machinery Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- shanghai

- Supply Ability

- 50 Sets Per Month

- Delivery Time

- 3 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- in full containers for edge board machine

- Main Export Market(s)

- Western Europe, Central America, Asia, North America, Eastern Europe, Middle East, Africa, South America

- Main Domestic Market

- All India

- Certifications

- SGS/CE

About V Notching Corner Protector Machinery

Technical parameter:

- 14 layers festoon paper stand

- Glue station

- Kraft liner wrapping part

- 4 /5 wheels forming and pressing part

- Die notching and cutting unit

- Conveyor belt

- Stacking overlap

- Collection table

Working flow of making paper edge boards and corner boards

- Slitting jumbo roll into small reels per the different edge board sizes

- Put small reels onto the edge board machine paper stands

- Passing all layers to the whole line

- Put down pressing wheels by cylinders

- Wrapping the kraft paper to full wrapping the inside layers

- Start glue pupm, feed glue on paper

- Give slow speed to start edge board machine

- Check and adjust the folding edges, measure the length

- Speed up and start belt and auto stacker

- Collect edge boards and packing manually or by packing machines

Features of Edge Protector machines

- 4 -5 sets of 3KW SEW motors

- 4 sets of big and solid pressing rollers

- 1 set of 90 degree die

- MISUBISHI frequency converter

- DELTA servo control system

- Schneider relay, contactor, terminals, breaker

- Omron encoder

- Wall size 15*15mm-100*100mm (120-150mm upon request)

- Die notching size 30mm-100mm

- Top cutting speed 40-60m/min

- Top notching speed 25m/min

- Die notching thickness 1-5mm

- Thickness 1.5mm -10mm

- Min cutting length online 50mm

- Buzzer alarm

- Overall size :L25000*D3500*H2500mm

- Power 19-31KW

Longer service life

- Sturdy construction

- Easy to operate

Specification

| Model |

ZHJ120A |

|

Width of edge |

15-120mm for both equal and unequal |

|

|

0-50m/min

|

|

Thickness |

1.5mm-10mm |

|

Max layer |

14 layer |

|

Paper demand |

Outer Kraft paper or similar paper 160g, inner paper 300g |

|

Voltage |

220V/380V/410V-440V |

|

Power |

25KW |

|

Serve cutting |

|

|

Gluing method |

Both single side and double sides |

|

Adjustment of roller |

Minute adjustment for left and right and up and down by air pressure |

|

Overall Length |

L24000*W1200*H1500mm |

|

Overall weight |

5Ton |

High-Capacity Performance

This automatic V Notching Corner Protector Machinery achieves a rapid production rate of 40 meters per minute, making it suitable for businesses with high output requirements. Its heavy-duty design supports rigorous industrial use while maintaining consistent performance standards, helping you meet demanding schedules with ease.

Advanced Control and Durability

Equipped with PLC control, the machinery offers precise automation for streamlined production and minimal manual intervention. Constructed from rust-proof stainless steel, it provides longevity and resistance to harsh work environments, ensuring sustained efficiency and lower maintenance costs over time.

FAQ's of V Notching Corner Protector Machinery:

Q: How does the V Notching Corner Protector Machinery operate?

A: The machine functions automatically using an electric drive and PLC control system. Operators set the requirements, and the machinery consistently produces V-notched edge protectors at a speed of 40 meters per minute, with minimal manual input needed.Q: What materials are used in constructing the machine?

A: This machinery is built from high-quality, durable stainless steel, ensuring rust-proof properties and enabling it to withstand tough industrial conditions for prolonged durability and operational reliability.Q: When is routine maintenance recommended?

A: Regular inspection and maintenance are advised every 3 to 6 months to assure optimal operation. With its rust-proof design, general cleaning and occasional part lubrication usually suffice, but always consult your warranty and user manual for specifics.Q: Where can the machinery be installed?

A: The machinery is suitable for installation in industrial facilities, manufacturing hubs, or warehouses with access to 220-440V electric power and ample space to accommodate its substantial dimensions.Q: What is the typical process for using this machine?

A: Feed the base material into the automatic machine, set the PLC control parameters, and initiate the operation. The system then executes precise V notching and edge protector shaping, yielding finished products rapidly and efficiently.Q: What are the main advantages of using this machinery?

A: Key benefits include its high production speed, minimal manual labor owing to automation, robust build quality for longevity, and a rust-proof finish that reduces maintenance, all backed by a one-year warranty.Q: How is the machinery powered and controlled?

A: Operating solely on electric power, the V Notching Corner Protector Machinery utilizes a 27KW electric supply and a PLC control system, allowing for easy monitoring and adjustments throughout the production process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Edgeboard Notching Machine 120AS Category

Paper Edge Protector Machine

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Voltage : 220440 Volt (v)

Control System : PLC Control

Weight (kg) : 5000 Kilograms (kg)

Automatic U shape and flat board edge protector machine

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Voltage : 220440 Volt (v)

Control System : PLC Control

Weight (kg) : 5000 Kilograms (kg)

U Profile Edge Protector Machine

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Voltage : 220440 Volt (v)

Control System : PLC Control

Weight (kg) : 5000 Kilograms (kg)

Cardboard Corner Board Making Machine

Minimum Order Quantity : 1 Set

Voltage : 220440 Volt (v)

Control System : PLC Control

Weight (kg) : 5000 Kilograms (kg)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry