Paper Flat Cardboard and Angle Board Machine

Paper Flat Cardboard and Angle Board Machine Specification

- Type

- Other

- Material

- Stainless Steel

- Feature

- Rust Proof, Highly Efficient, Durable, Less Power Consumable

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 24.5 Watt (w)

- Voltage

- 220-440 Volt (v)

- Weight (kg)

- 5000 Kilograms (kg)

- Dimension (L*W*H)

- 25000*1300*1700 Millimeter (mm)

- Color

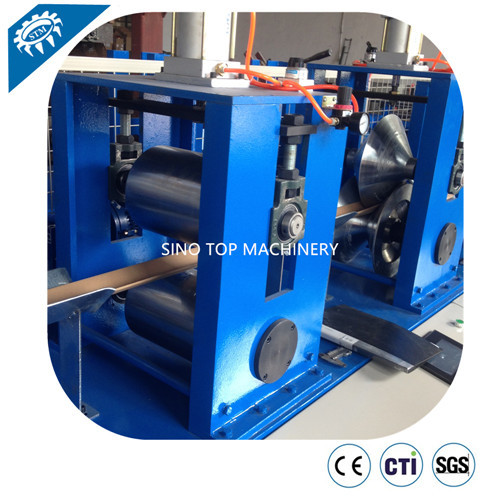

- Gray& Blue

- Warranty

- 1 Year

Paper Flat Cardboard and Angle Board Machine Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- SHANGHAI

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 50 Sets Per Month

- Delivery Time

- 3 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- edge protector

- Main Export Market(s)

- North America, South America, Eastern Europe, Middle East, Africa, Central America, Western Europe, Asia

- Main Domestic Market

- All India

- Certifications

- CE

About Paper Flat Cardboard and Angle Board Machine

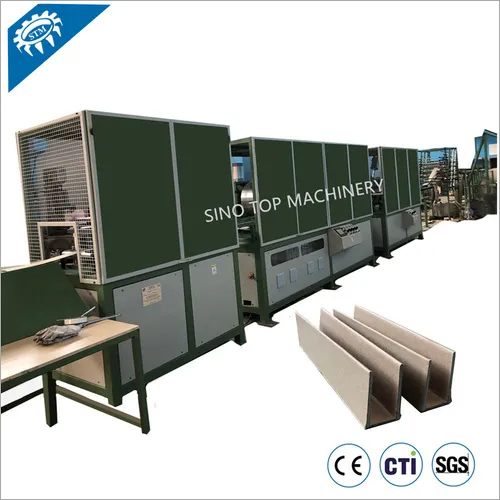

To meet the diversified requirements of our prestigious clients, we are manufacturing and supplying an assorted range of 120AP Paper Flat Cardboard and Angle Board Machine. Our highly skilled professionals manufacture this product using top quality components that are procured from the trustworthy vendors of the market. In order to ensure quality, it is stringently tested on various parameters. This 120AP Paper Flat Cardboard and Angle Board Machine is widely used in paper and textile industry.

Features:

- Robust construction

- Optimum performance

- Easy installation

Features :

- PLC control panel

- long time service life

- make drier and harder edge protector

- Heating function

- one machine can make both flat laminating cardboard and edge protector

- crane and pneumatic way to load paper reels, safely and easy

- smart but useful

- Large size range for wing width :15mm-120mm

- larger range of thickness: 1.5 to 10mm

- both single and double sides gluing

- no limited of length

- online shortest cutting length at 50mm

- punching corners online

- automatic stacking

- Single color printing online

Applications:

- one machine can make both flat board and V shape edge protector

- one machine can make both flat board and U shape edge protector

- you can choose one machine one shape or one machine with different shapes

- 50mm length cutting online

- to make paper edge protector for packing

Technical Specifications :

|

Model |

ZHJ-120AP |

|

Width |

15 to 120mm |

|

Wall Thickness |

1.5 to 10mm |

|

Speed |

0 to 45m/min, speed depends on edge board sizes and paper quality |

|

Cutting Length |

50mm-endless |

|

Cutting Accuracy |

1 mm |

|

Power |

120A to 24.5KW/Automatic Collection: 1.9KW |

|

Max Layer of Paper |

13 layers + 1 surface |

|

Paper demanding |

Surface Kraft paper 160g, inner paper 300g |

|

Cutting way |

Servo cutting, fly shear |

|

Gluing way |

Both single and double faced |

|

Overall size |

L25000*D1300*H1700mm (including automatic collection) |

|

Total Weight |

5 Ton |

|

Operation |

2 persons |

Advanced Manufacturing Efficiency

Engineered for high throughput, this machine delivers up to 5 tons of flat cardboard and angle board daily. The automated PLC control enhances precision and minimizes manual intervention, reducing operational costs while maximizing production output. Its efficient use of power ensures significantly lower energy consumption, making it a cost-effective solution for large-scale manufacturing.

Durable Rust-Proof Construction

Built with premium stainless steel and advanced anti-corrosive finishes, this machine resists wear and production-related rust, guaranteeing a long service life. The choice of sturdy yellow, blue, or gray exteriors not only adds to its aesthetic appeal but also ensures continued reliability, even under demanding industrial conditions.

Flexible Operation and Safety

Accepting power inputs of 220 to 440 volts, the machine is suitable for different factory settings. Its integrated safety features, computerized (or non-computerized) PLC system, and ease of operation make it accessible for both skilled and semi-skilled operators. Maintenance is streamlined, and the comprehensive one-year warranty provides added confidence.

FAQ's of Paper Flat Cardboard and Angle Board Machine:

Q: How does the Paper Flat Cardboard and Angle Board Machine operate?

A: The machine operates automatically using a PLC control system, enabling seamless production of flat cardboard and angle boards. Simply set the required parameters on the PLC interface, and the electric drive system manages the production process with minimal manual supervision.Q: What materials are compatible with this machine?

A: This machine is compatible with paper as the primary raw material and is constructed with durable stainless steel to ensure robust operation and longevity.Q: When should maintenance be performed on this machine?

A: Regular maintenance is recommended every three to six months, depending on usage intensity. The rust-proof design reduces maintenance needs, but it is essential to keep moving parts clean and periodically check the electrical system for optimal performance.Q: Where is this machine typically used?

A: This machine is widely used in manufacturing facilities, packaging industries, and by suppliers and exporters needing high-volume production of cardboard and angle boards, especially in industrial settings throughout China.Q: What are the main steps in the manufacturing process with this machine?

A: The process involves loading raw paper material into the machine, setting operational parameters on the PLC control, and allowing the machine to automatically process, press, and cut the paper into flat boards or angle shapes as required.Q: What are the key benefits of using this machine?

A: Key benefits include high production capacity, low power consumption, a durable rust-proof structure, efficient PLC-controlled automation, and a reliable one-year warranty for peace of mind.Q: How can users maximize the efficiency of the machine?

A: To ensure maximum efficiency, operators should follow recommended maintenance schedules, use high-quality raw materials, and select appropriate settings on the PLC control system tailored to their specific product requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Edgeboard Notching Machine 120AS Category

Paper Edge Protector Machine

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Power Source : Electric

Warranty : 1 year

Product Type : Paper Lamination Machine

Drive Type : Electric

Automatic U shape and flat board edge protector machine

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Power Source : Electric

Warranty : 1 Year

Product Type : Paper Lamination Machine

Drive Type : Electric

U Profile Edge Protector Machine

Price 28000 USD ($) / Set

Minimum Order Quantity : 1 Set

Power Source : Electric

Warranty : 1 year

Product Type : Dry Lamination Machine

Drive Type : Electric

Cardboard Corner Board Making Machine

Minimum Order Quantity : 1 Set

Power Source : Electric

Warranty : 1 year

Product Type : Other

Drive Type : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry