honeycomb core for funiture filling

MOQ : 100 Packs

honeycomb core for funiture filling Trade Information

- Minimum Order Quantity

- 100 Packs

- Supply Ability

- 1000 Packs Per Week

- Delivery Time

- 7 Days

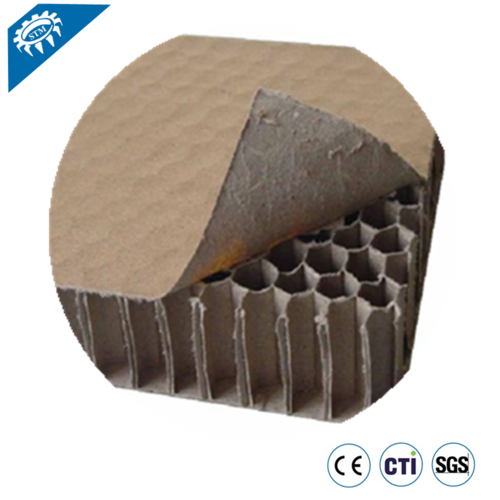

About honeycomb core for funiture filling

Paper Honeycomb Boardhigh tension corrugated core paper and kraft surface paper for packaging and advertising.

Advantage of paper honeycomb board

- lightweight

- Environmental

- Recyclable

- Reused

- low cost

- stronger than corrugated boxes

Application of honeycomb board

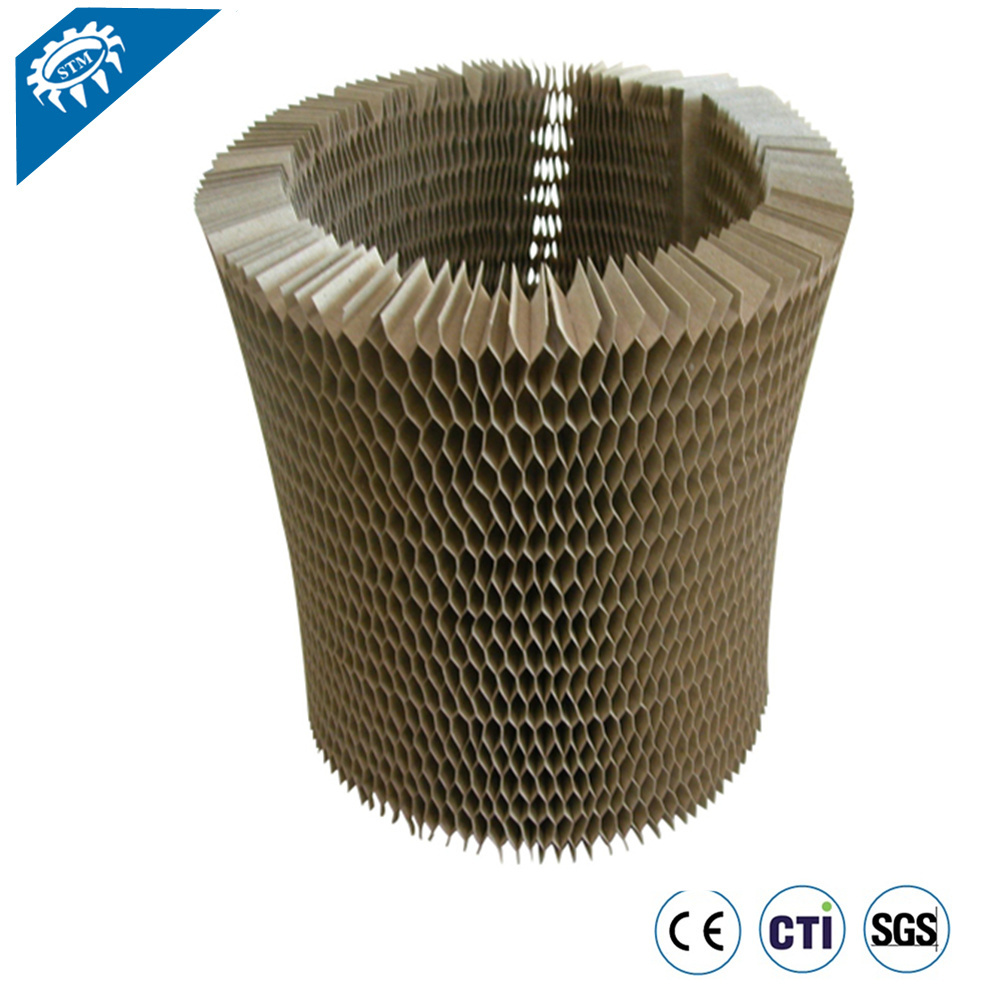

- filling materials for furniture door table

- to make honeycomb pallets honeycomb heavy-duty cartons cushion material

- to separate goods as clapboard

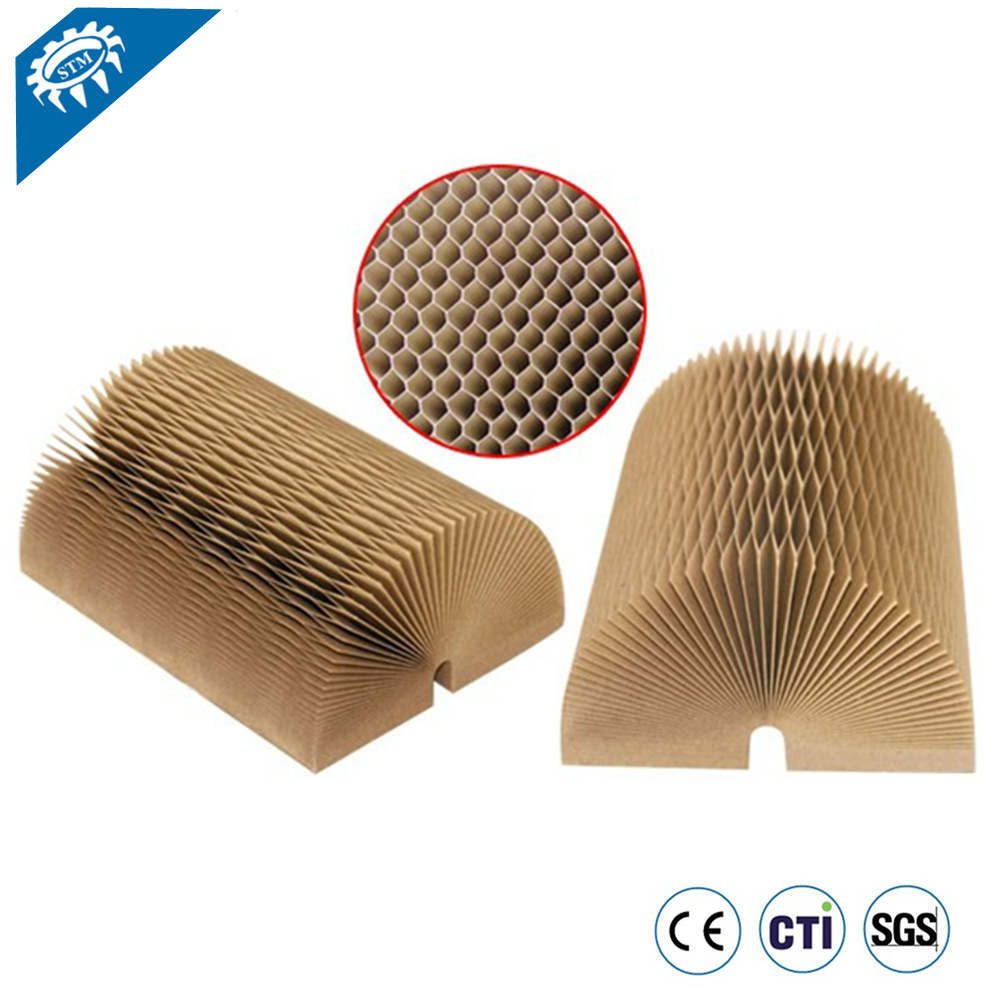

- to hold different shapes of goods with die-cutting

- to print for advertising display

- Expo display

- paper furniture

Superior Moisture Resistance

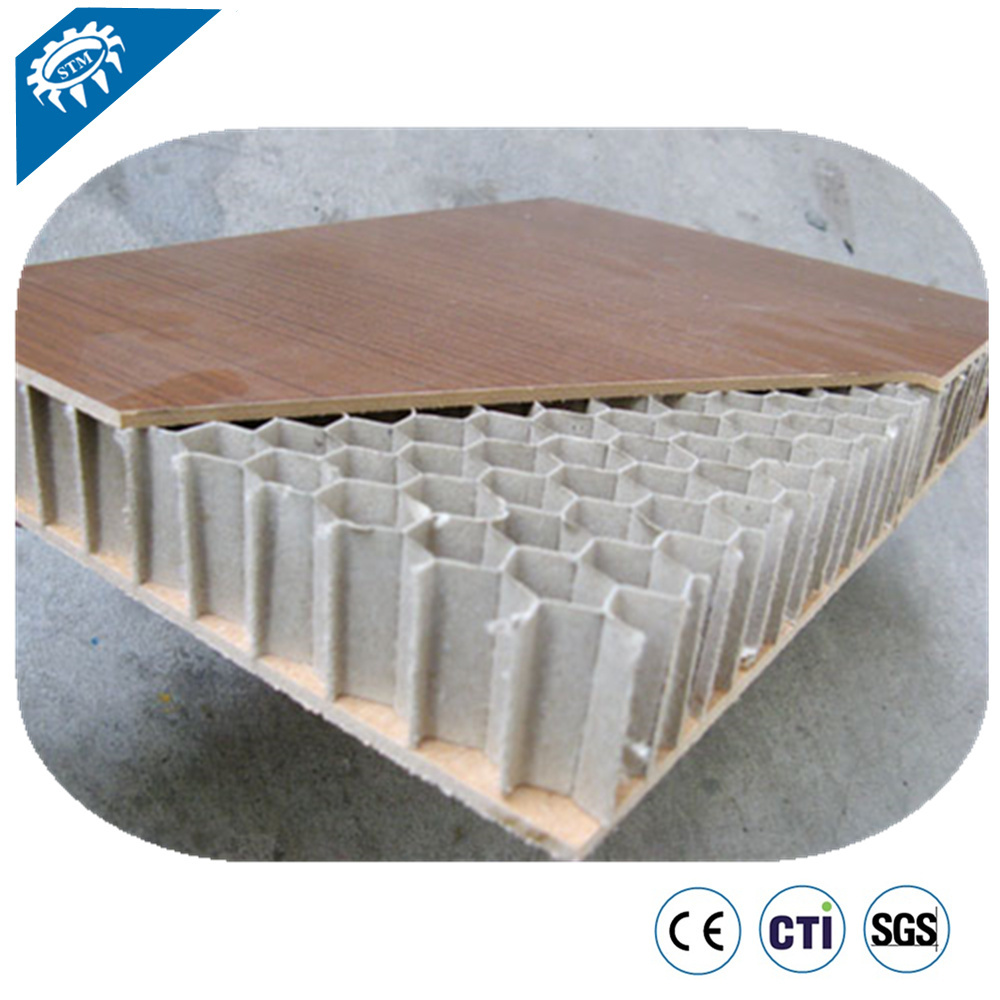

The honeycomb core's specialized coated surface provides excellent moisture-proof protection, making it ideal for furniture exposed to variable humidity levels. This feature safeguards interiors and prolongs the life of completed products, assuring quality and reliability.

Sustainable and Lightweight Solution

Constructed using recyclable paper, our honeycomb core emphasizes sustainability while maintaining remarkable strength. Its lightweight design is perfect for furniture, as it reduces overall product weight without compromising structural stability.

FAQ's of honeycomb core for funiture filling:

Q: How is the honeycomb core used in furniture manufacturing?

A: The honeycomb core serves as a lightweight, durable filling inside furniture panels such as tables, doors, and shelves. It provides structural integrity while minimizing overall weight, making furniture easier to handle and transport.Q: What benefits does the moisture-proof coating offer?

A: The moisture-proof coating shields the paper material from humidity and spills, preventing warping and preserving the integrity of furniture over time. This ensures lasting durability and consistent quality.Q: When should I consider using a honeycomb core for furniture filling?

A: You should consider honeycomb core when you need a furniture solution that is lightweight, strong, cost-effective, and environmentally friendly. It's particularly beneficial for large pieces where traditional solid fillings would add significant weight.Q: Where is this honeycomb core manufactured and supplied from?

A: Our honeycomb core is manufactured and supplied from our facilities in China. We serve customers both domestically and internationally as a distributor, exporter, manufacturer, supplier, and trader.Q: What is the process for installing the honeycomb core in furniture?

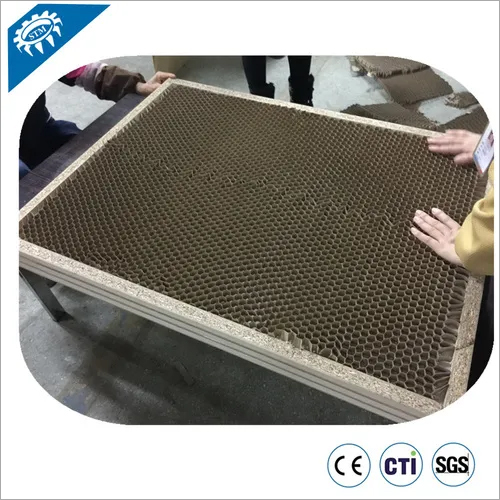

A: Typically, the honeycomb core is sandwiched between two rigid face sheets, such as MDF or plywood, and then sealed within the frame. The coated paper core is securely bonded to the panels to form a sturdy, composite structure.Q: What standard sizes are available for the honeycomb core?

A: We provide honeycomb cores in standard sizes suitable for a variety of furniture applications. Customization options are also available upon request to meet unique project requirements.Q: How does using honeycomb core benefit furniture businesses?

A: Businesses benefit from reduced material costs, lighter shipping weights, and environmentally responsible sourcing. The honeycomb core enhances furniture performance while supporting sustainability and efficient manufacturing processes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pallet Assembly Machines Category

Honeycomb Core for pallet

Minimum Order Quantity : 100 Packs

Coating : Coated

Feature : Moisture Proof

Color : Brown

Size : Standard

Material : Other, Honeycomb Core

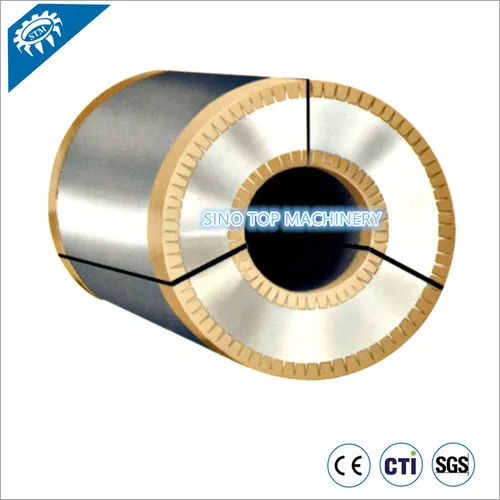

Coil Edge Protector

Minimum Order Quantity : 100 Packs

Coating : Uncoated

Feature : Moisture Proof

Color : Brown

Size : Standard

Enviromental advertising printing honeycomb board

Minimum Order Quantity : 100 Packs

Coating : Coated

Feature : Moisture Proof

Color : Brown

Size : Standard

Material : Other, honeycomb board

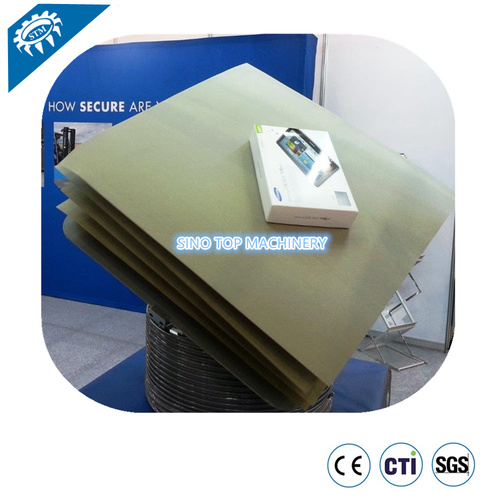

Anti-slip sheet

Minimum Order Quantity : 100 Packs

Coating : Coated

Feature : Moisture Proof

Color : Brown

Size : Standard

Material : Other, paper

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry