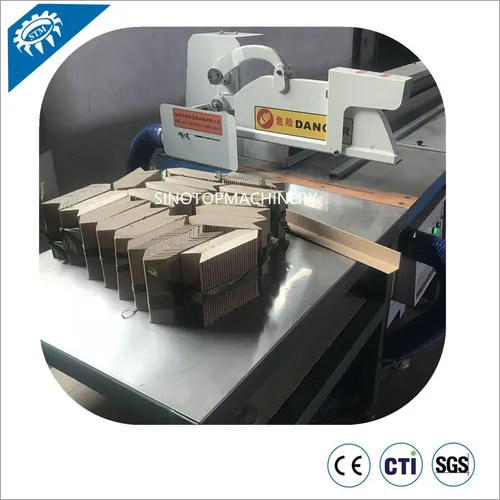

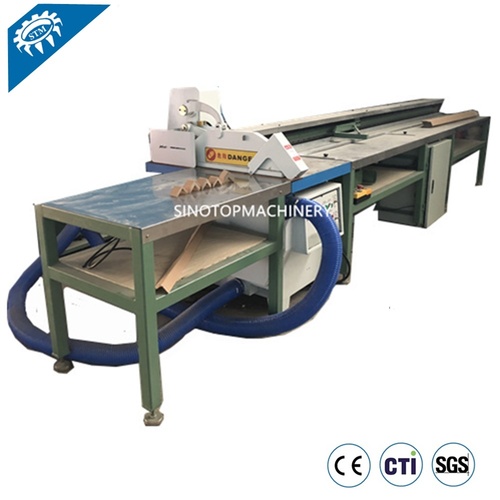

Edge Board Cutting Machine

Price 9500 USD ($)/ Set

MOQ : 1 Set

Edge Board Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Shanghai

- Supply Ability

- 50 Sets Per Month

- Delivery Time

- 3 Months

- Main Export Market(s)

- Western Europe, Central America, North America, Eastern Europe, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

About Edge Board Cutting Machine

Technical Specification :

- 400 model

- Automatic feeding and cutting

- Cutting angle 45-90

- Max cutting width 280mm

- Max cutting height 120mm

- Diameter of blades 355-455mm

- Speed RPM 1400

- Working pressure 6-8kg

- Dust collection

- Power:380V/50HZ/5.0kw/customized

- Max length of mother edge board 2.5m

- Min length of edge board 40mm

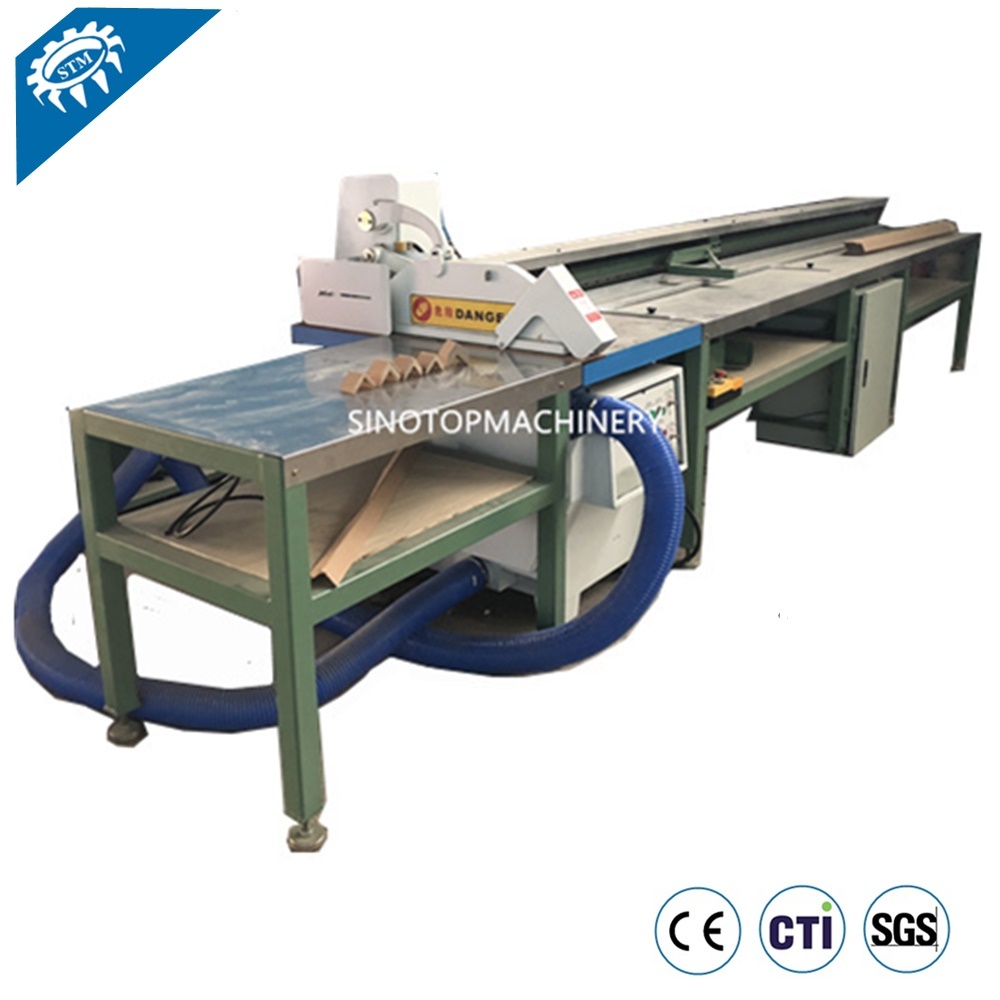

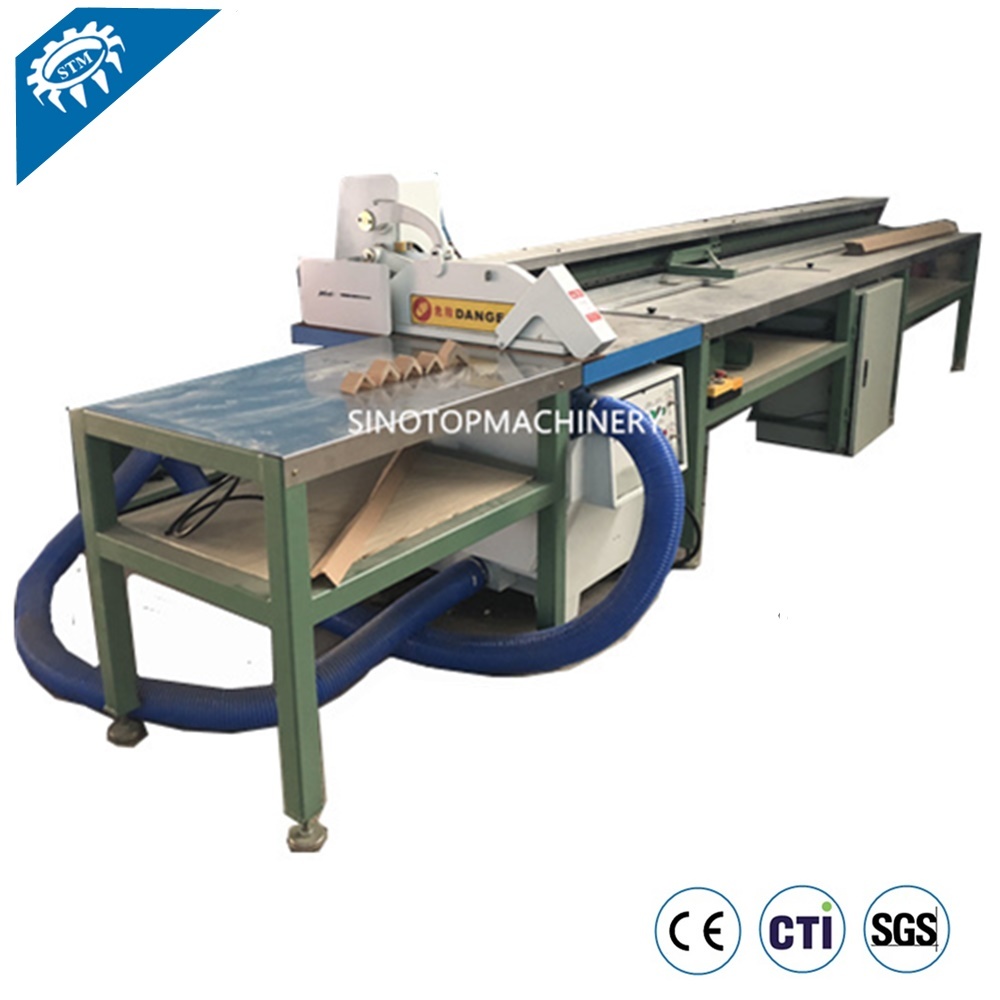

- L4000*D1000*H1300mm

- Leading time 25 working days

Efficient Industrial Edge Board Cutting

The Edge Board Cutting Machine is engineered for precision and speed in cutting edge boards, making it a valuable asset for manufacturing environments. Its reliable electrical operation and automatic functionality reduce manual labor, while the robust painted finish ensures durability. Industrial users benefit from its large processing capacity, making bulk order fulfillment easier and faster.

Reliable and Durable Construction

With its gray and blue painted exterior, the machine resists wear and maintains a professional appearance in demanding industrial settings. Its substantial size accommodates various board dimensions, ensuring compatibility with a wide range of production requirements. The 1-year warranty provides peace of mind for new users.

FAQ's of Edge Board Cutting Machine:

Q: How does the automatic operating system of the Edge Board Cutting Machine work?

A: The Edge Board Cutting Machine utilizes an automatic operating system that streamlines the cutting process, allowing users to set parameters and let the machine handle cutting tasks with minimal supervision. This automation enhances productivity and ensures consistent results every time.Q: What are the main benefits of using this edge board cutting machine in an industrial setting?

A: Key benefits include increased cutting efficiency, reduced manual labor, consistent quality of cut boards, and the ability to handle large quantities quickly. Its durable painted surface and automatic features contribute to long-term reliability and operational savings.Q: Where is this Edge Board Cutting Machine manufactured and available for export?

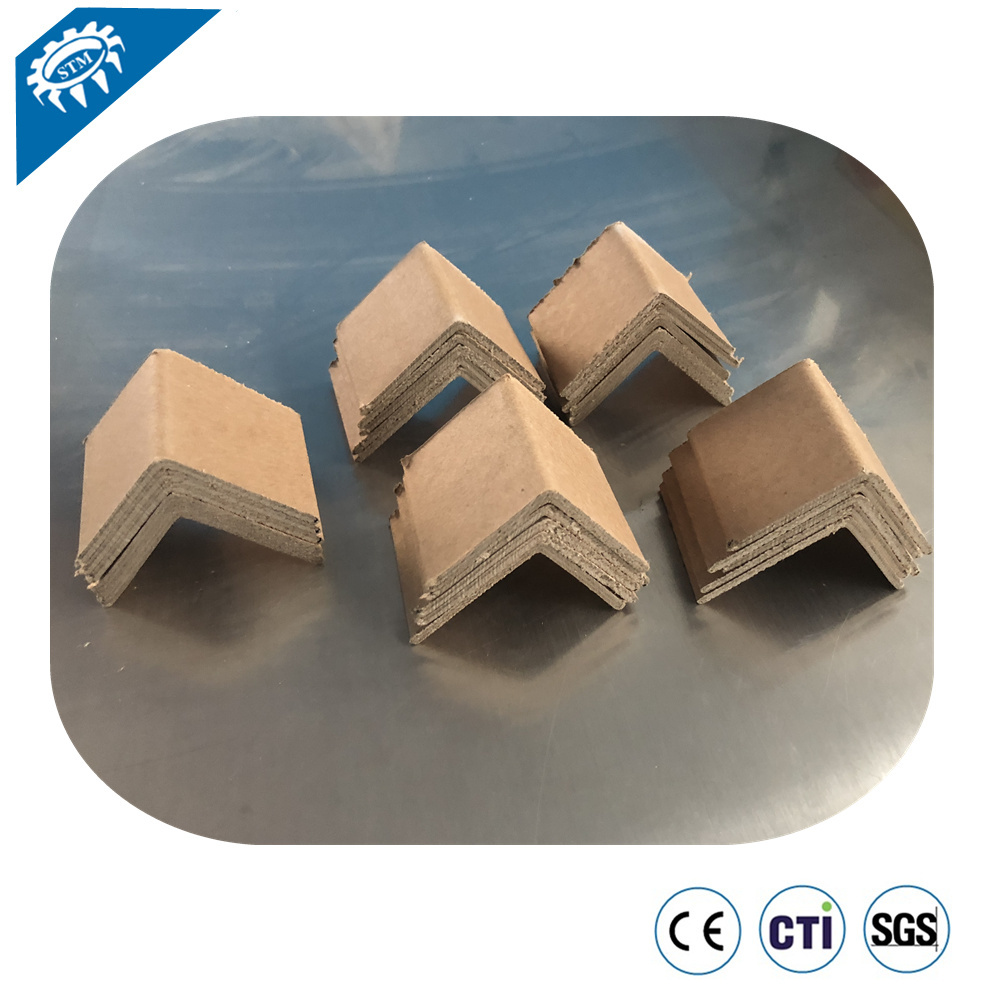

A: The machine is manufactured in China and is available for distribution, export, supply, and trade to various international markets. Chinese manufacturers ensure adherence to industrial standards and provide support for global customers.Q: What types of edge boards can this machine process, considering its dimensions?

A: With dimensions of 4000*1000*1300 mm, the machine accommodates a wide variety of edge board sizes commonly used in packaging, construction, and other industrial applications, ensuring versatility for different operations.Q: How much power does the Edge Board Cutting Machine require, and is it energy-efficient?

A: The machine operates on a low power consumption of just 5 Watts, making it energy-efficient for continuous industrial use. Its design focuses on minimizing energy costs without sacrificing performance.Q: What is the process for maintaining the Edge Board Cutting Machine?

A: Routine maintenance involves cleaning the machine's painted surfaces, checking electrical connections, and ensuring moving parts are well-lubricated. Regular maintenance helps uphold its 1-year warranty and prolongs equipment life.Q: When should industrial users consider replacing their edge board cutting machine?

A: Consider replacement if your current machine lacks automation, consumes excessive power, shows signs of significant wear, or can no longer meet production demands. Upgrading to this model provides increased efficiency and better long-term value.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Offline Edgeboard Recutter Category

Cardboard Edge Protector Cutting Machine

Price 9500 USD ($) / Set

Minimum Order Quantity : 1 Set

Warranty : 1 year

Operating Type : Automatic

Heating System : Other

Capacity : 2 Ton/day

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry