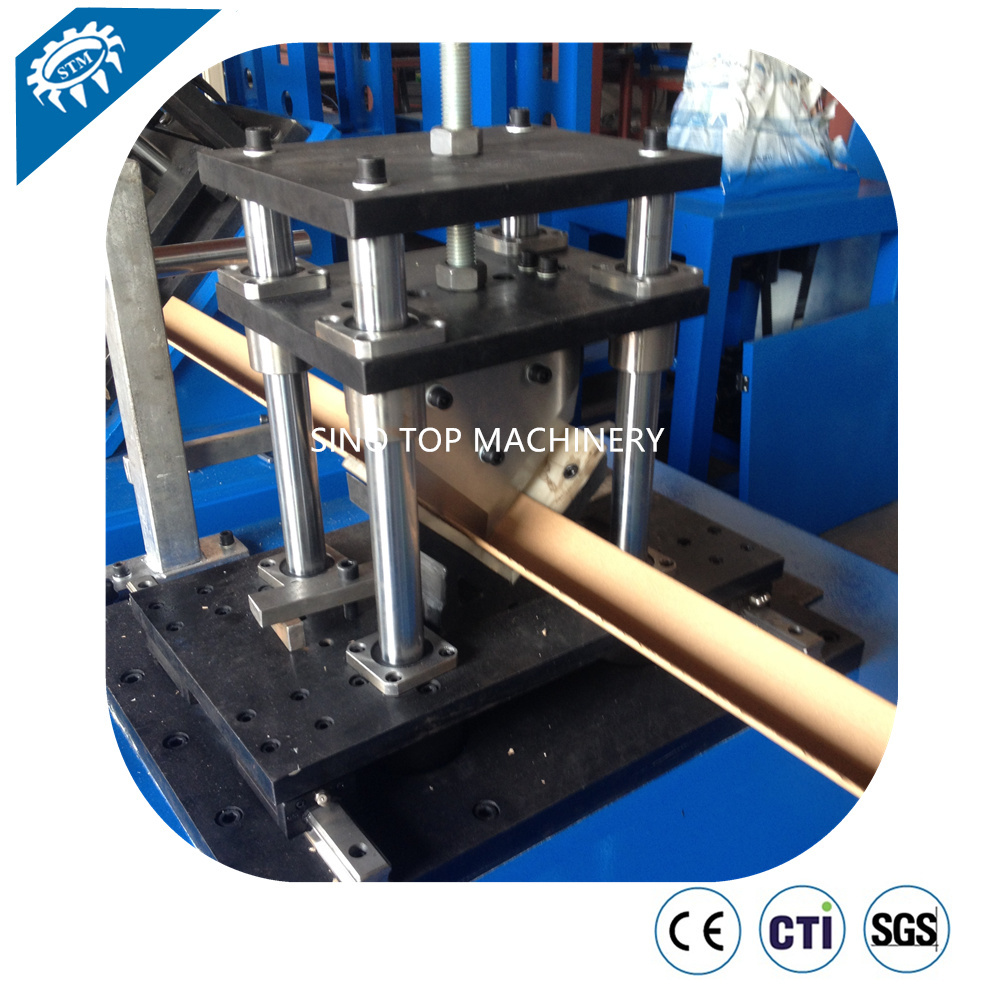

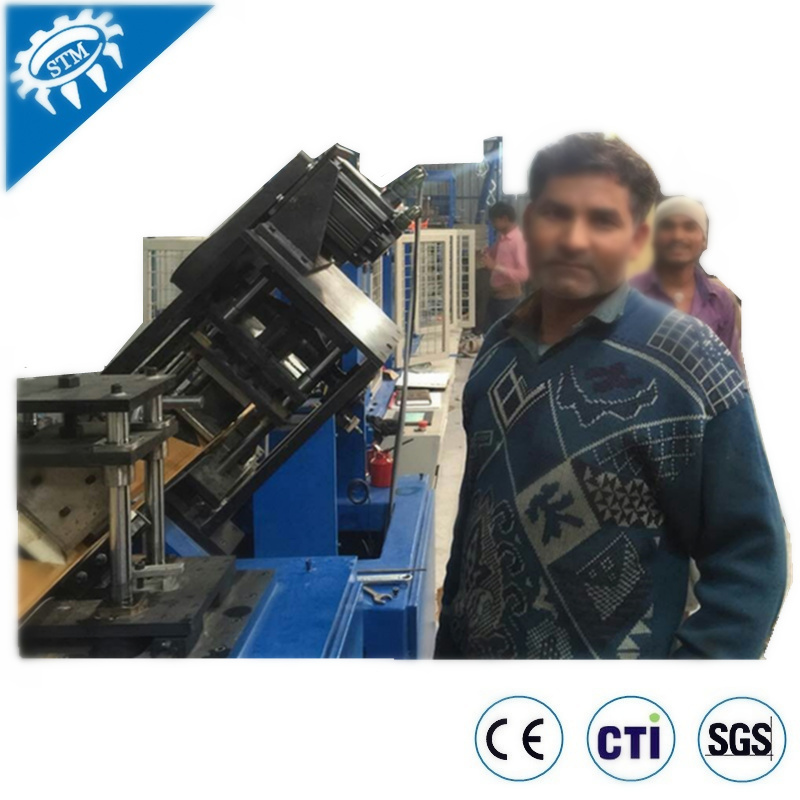

China edgeboard angle board die notching machine

Price 1000-17000 USD ($)/ Set

China edgeboard angle board die notching machine Specification

- Type

- Edge board machine

- Material

- Stainless Steel

- Feature

- Highly Efficient, Heavy Duty Machine, Rust Proof, Durable, Less Power Consumable

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 220-440 Volt (v)

- Color

- Green

- Warranty

- 1 Year

China edgeboard angle board die notching machine Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Shanghai

- Supply Ability

- 50 Sets Per Month

- Delivery Time

- 3 Months

- Main Export Market(s)

- Western Europe, Central America, North America, Eastern Europe, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

About China edgeboard angle board die notching machine

Advantages of our Edgeboard machines.

- French tech with independent motors each forming wheels, even one motor breaks, the other motors can still work. No need to stop the machine, traditional machines have only one motor.

- The faster and stable speed with four motors

- Festoon system paper stand with hoist, safe and easy, saving space

- Brakes on gluing station to adjust paper tension( sometimes paper reels are not rewinded properly, brakes can help enlarge paper tension)

- Metal and durable glue scraper

- Easy operation surface paper wrapping section, the whole set can be moved when making unequal size edge boards

- 4 sets of forming wheels, heavy, big and solid

- 4 sets of German brand motors

- servo cutting

- whole piece of cutting blades

- thickness of edge boards, 1.5-10mm

- Edge board wall sizes: 15-120mm

- conveyor and automatic stacker

- single color printer

- Top speed 40m/min

- Space needed L25*D3.5*H2.5m

Superior Efficiency and Durability

Crafted from high-quality stainless steel and engineered for continuous operation, this edgeboard machine maximizes production output with minimal maintenance needs. Rust-proofing and robust construction extend its service life, while the PLC control assures consistent performance during heavy-duty applications.

Automated Precision for Edgeboard Die Notching

This machine employs advanced PLC (Programmable Logic Controller) technology, enabling seamless, automated processes with precise die notching at high speeds. Its automatic grade minimizes manual intervention, reducing labor costs and enhancing repeatability in packaging component production.

FAQ's of China edgeboard angle board die notching machine:

Q: How does the PLC control system enhance the machine's operation?

A: The PLC (Programmable Logic Controller) control system provides precise command over the die notching process, allowing for accurate and repeatable edgeboard manufacturing. This automation boosts productivity and ensures consistent product quality with minimal manual input.Q: What are the main benefits of using this edgeboard angle board die notching machine?

A: Key benefits include high operational efficiency, durable stainless steel construction, rust-proof qualities, reduced power consumption, and an automatic system that saves on labor and enhances precision. Its heavy-duty design ensures reliable long-term use.Q: What materials can be processed with this machine?

A: This edgeboard machine is designed to work specifically with materials needed for edgeboard or angle board production, such as strong paperboard or similar raw materials. The stainless steel body makes it suitable for continuous industrial applications.Q: When should maintenance be performed on this machine?

A: While the machine is built for durability and heavy-duty use, routine inspections and basic maintenance are recommended according to manufacturer guidelines-typically, this involves checking the die, electrical connections, and cleaning the stainless steel components for optimal performance.Q: Where can this machine be installed for best results?

A: Ideal for manufacturing facilities, packaging factories, or commercial production lines with suitable voltage supply (220-440V). Ensure proper space, ventilation, and safety protocols are in place to maximize the advantages of its automation and efficiency.Q: What is the typical process of die notching using this equipment?

A: The raw edgeboard material is fed into the machine, where automated die notching is carried out under the control of a PLC system. The process is fast, accurate, and repeatable, resulting in uniformly notched edgeboards ready for packaging applications.Q: Is this machine suited for exporters and suppliers?

A: Yes, as a supplier, distributor, exporter, manufacturer, or trader in China, this machine offers reliability and economy for large-volume production, helping businesses scale up while maintaining consistent product quality and efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Offline V Puncher Category

V die punching online edge board machine

Price 1000-17000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Feature : Rust Proof, Heavy Duty Machine, Durable, Less Power Consumable, Highly Efficient

Warranty : 1 year

Weight (kg) : 8000 Kilograms (kg)

Cardboard Edge Protector die notching Production Machine

Price 1000-17000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Feature : Rust Proof, Durable, Less Power Consumable, Highly Efficient

Warranty : 1 Year

Weight (kg) : 5000 Kilograms (kg)

40m/min Paper Angle Board Machine

Price 1000-17000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Feature : Rust Proof, Highly Efficient, Durable, Less Power Consumable

Warranty : 1 Year

Weight (kg) : 7000 Kilograms (kg)

Fast Speed Edge Protector Making Machine

Price 1000-17000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Feature : Rust Proof, Durable, Less Power Consumable, Highly Efficient

Warranty : 1 Year

Weight (kg) : 5000 Kilograms (kg)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry